At ShipHawk sustainability is a core part of our supply chain strategy.

When building our modern Transportation Management System, TMS 2.0, we decided to take a different approach to an old problem. Instead of looking at boxes and pallets as primary units, we decided to consider real items (lamps, iPhones, watches, etc.). In doing so, we were able to make packaging a core component of the software. The result is a patent pending, hardware-free packing optimization that significantly reduces packaging materials and shipping costs.

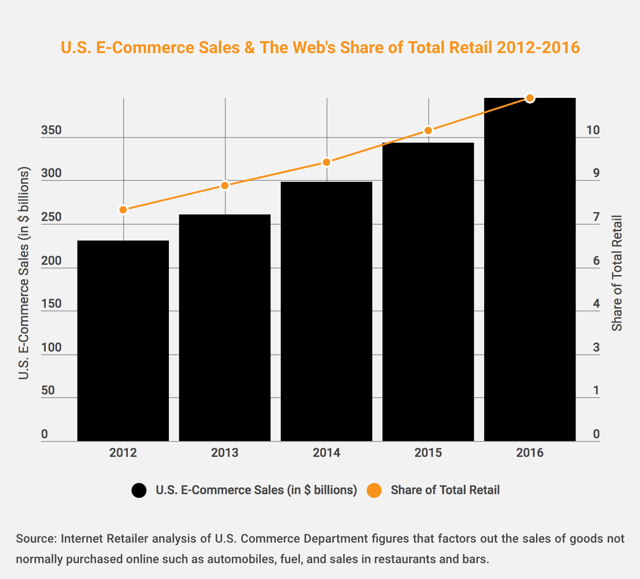

The Era of Instant Gratification

eCommerce is growing at an exponential rate due to the convenience it offers buyers. The online retailer wants to ensure that the product they are shipping arrives fast and in perfect condition in order to guarantee the customer has a positive experience and continues to buy from them. These needs do not align with a low packaging mentality. In fact, the opposite is true as retailers ship multiple boxes from multiple locations to fulfill each order. We’ve all received that infamous Amazon box that could hold a small chair with a small item inside. Or shown up after work to find a stack of boxes towering in front of our door.

Current processes and demanding buyers lead to the overconsumption of packaging materials, which has lead to more than 36 million tons of packaging waste filling our landfills.

To add insult to injury, buyers don’t appreciate the inconvenience of dealing with excessive packaging material. It is difficult to handle and properly dispose of.

Since 2009, Amazon customers have submitted 33 million packaging-related comments, ratings, and photographs to the company, according to the New York Times.

Reducing is the First Step

Companies are beginning to move towards recyclable packing materials in an effort to create less waste. However, ShipHawk decided to take this effort one step further - by reducing the amount of packaging used to begin with.

Our patent pending, hardware free packaging optimization takes the guesswork out of the shipping operation. By automatically leveraging an item’s true characteristics like original location, size, weight, void space, and even material composition, ShipHawk calculates the optimal box size and packing materials. The results? Companies save money, time, and resources on every shipment.  Before the eCommerce era, packaging was created for shelf appearance, often using excess materials to make it more visually appealing to the consumer.Online shopping greatly reduces the need for this type of packaging, allowing companies to be able to rethink the process entirely. Efficient packaging, however, is easier said than done.In fact, the Twin Cities region alone, generates over 3 million tons of solid waste, of which approximately 17 percent is pallets and cardboard boxes generated by businesses. ShipHawk aims to reduce this waste produced by businesses in order to make the ever growing eCommerce industry more sustainable and environmentally friendly.

Before the eCommerce era, packaging was created for shelf appearance, often using excess materials to make it more visually appealing to the consumer.Online shopping greatly reduces the need for this type of packaging, allowing companies to be able to rethink the process entirely. Efficient packaging, however, is easier said than done.In fact, the Twin Cities region alone, generates over 3 million tons of solid waste, of which approximately 17 percent is pallets and cardboard boxes generated by businesses. ShipHawk aims to reduce this waste produced by businesses in order to make the ever growing eCommerce industry more sustainable and environmentally friendly.

Plastic Packaging Impacts

According to the LA Times, over 9.1 billion tons of plastic have been produced since its creation in the 1950s. Plastic used in packaging currently accounts for 42% of this amount and is expected to continue to increase.Recycling does not prevent plastic consumption, but rather delays its eventual entrance into landfills. Researches have found that only 9% of total plastics have been recycled, 12% has been incinerated and 79% ends up in landfills or the environment.

The best and most effective way to prevent this trend from continuing into the future is to reduce plastic production and consumption. With packaging as the leading cause of plastic waste, reducing the amount of packaging required for each item would have a significant impact on the total waste.

ShipHawk’s packaging algorithm ensures that each item is shipped in the most efficient way, reducing waste and environmental impact.

A Greener Reputation

ShipHawk allows companies to reduce packaging materials, benefiting all parties involved.Companies can develop a greener reputation, while streamlining the shipment process and delivery time, increasing customer satisfaction.

Consumers expect companies to act in line with their expectations regarding product quality and delivery speed, but also environmental consciousness. ShipHawk allows businesses to use this as a major point of differentiation.

Back in 2008, Dell experienced a strong consumer backlash on social media regarding their computer packaging. Consumers value sustainability and want the companies they purchase from to support the same values.

Consumers have stated that they often feel guilty when ordering so many products online and embarrassed due to the amount of materials wasted in the delivery process. ShipHawk recognized this issue and found an automated solution to the packaging problem.

When companies utilize the correct amount of packaging, they illustrate their devotion to the environment to the consumer. These consumers are then much more likely to become repeat buyers because the environmental impact of new orders is much smaller than competitors.

Delivering to the Doorstep

Less packaging = less waste and energy used

In addition to reducing physical packaging waste, ShipHawk works to make the transportation process of orders more efficient, ultimately reducing the carbon footprint of an order even further. With ShipHawk’s multi-carrier, multi-mode TMS, shippers are able to optimize their delivery and reduce the amount of gas used to transport the package. Costs and resources are kept low benefiting both parties.

We are continuously working on achieving measurable sustainability goals within our own operations while also helping customers achieve sustainability goals of their own.