Buying a Transportation Management System (TMS)

Fast and free has never meant so much

Let’s face it, the world has changed. Back when most Transportation Management Systems were built, Amazon was just a rainforest and Ali Baba was still a poor woodcutter (Yes, I had to look that up). Whether they are viewed as competition or not, these companies have fundamentally changed buyer expectations.

Ecommerce continues to grow at exponential rates, expected to eclipse $500 billion in 2020 in the US alone. And shipping is growing faster than eCommerce.

Back in 2012, FedEx made 3.4 million daily deliveries. In 2019 they made 15 million.

Meanwhile, for most shippers, shipping is their second most expensive cost after COGS (Cost of Goods Sold) and it’s growing at a rate of over 5% every year.

So here we are, with shippers looking for modern transportation management systems (TMS) that can either help them survive or give them an edge. Like an old dog, legacy TMS software can’t learn new tricks. So they are stuck with a bunch of questions and few trustworthy sources to leverage for honest answers.

Consider the following

- How do shippers compete?

- Are shippers current processes the right processes?

- How do shippers ensure the lowest shipping cost for every order?

- How do shippers eliminate costly manual workflows?

- What system is right for today’s complex operations?

- How much should shippers spend?

- Will the ROI really amount to the amounts TMS vendors are indicating on their fancy spreadsheets?

Don’t panic. We have answers. And they’re loaded with helpful information as well. No matter what TMS is bought in the end, we will cover the important details and point shippers in the right direction.

What is ShipHawk and why did we build it?

We promise not to be one sided throughout the entire article, but we believe it is important to understand how we view the market so shippers know why we decided to build a modern transportation management system.

In 2015, shortly after we started the company, I wrote a blog post titled We Believe. The purpose of the post was to share with prospective customers why we started the company. We’ve seen the writing on the wall for a long time. “Main Street is now nothing more than a tourist attraction thanks to the Walmart and Target sitting just outside town and the often overused Amazon or Alibaba bookmark in your browser. Local, family-owned businesses have been replaced by jobs in massive regional warehouses, where the human is the last great inefficiency and is being rapidly replaced by robots.”

Legacy TMS solutions were built for the only businesses that could afford them, big ones. The efficiencies this technology brought to businesses at the time gave those shippers a serious competitive advantage. But as markets and supply chains were rapidly evolving, legacy TMS technology didn’t change much. By 2011, the know-how was available to make this tech available to shippers of all sizes, enabling them to have the same power as the big shippers, but nobody was building it. In addition, the world had changed, and shippers were sending more than small brown boxes and perfect 4x4 pallets. The tech that was available wasn’t capable of handling new and old freight types.

Enter ShipHawk

We decided to step up to the plate and take a completely different approach to the problem. Instead of focusing on boxes and pallets, we built ShipHawk to work with real items. Chairs, dressers, chocolate bars, skateboards, books, backpacks and all the other items that people ship these days. By considering real items, we were able to build a system that offers shippers significantly more data, which resulted in additional automations and lower shipping prices. But the benefits of our approach didn’t end there.

Here is the initial set of opportunities we set out to realize:

10 Initial TMS Goals

- Build an enterprise grade transportation management system that offers Fortune 500 power (at lower prices) that small/medium sized shippers can afford

- Allow shippers to accurately determine shipping costs upfront so order margins are protected

- Automate fulfillment to reduce costs, errors, and damage

- Support lightning fast implementation times

- Offer transparent, easy to understand pricing

- Facilitate shipping all products, not just those in pretty brown boxes

- Make the system highly configurable - everyone has their own way of doing things, right?!

- Define optimization as more than calling a few carrier APIs

- Start every shipment with packing, not with shipping, so as to provide additional opportunities to reduce shipping costs

- Provide all data in real time

This was a tall order. The industry is old and most of the dominate players are big, slow and resistant to change.

Why did big company TMS software not offer these solutions? In other words, how exactly did we get here with an unmet need this big?

A History of Transportation Management

We’re so used to getting our deliveries overnight – or even within hours – that we forget how far transportation and delivery has come.

It began with the US Postal Service

The United States Postal Service (USPS) was created in 1775. Benjamin Franklin was the first postmaster general. Until a new law in 1912, the USPS couldn’t deliver packages weighing more than four pounds; this gave package delivery companies a distinct advantage. As package delivery companies prospered, Congress finally changed that law, allowing the USPS to handle packages up to 11 pounds, within certain size parameters.

Much like e-commerce exploded with the internet, sales via mail-order companies rapidly grew under the new law. Subsequently, the postal service increased the weight limit to 70 pounds, and included a sizing algorithm as well.

UPS spots an opportunity

Just as the USPS adapted to market needs, so did other delivery companies, based on available transportation modes and government regulations. UPS is one of the carriers that stayed small and took advantage newer operational models. They started as a Seattle-only messenger service in 1907, delivering small packages (or more often, actual messages) transported by bike or foot. In 1913, they bought a dedicated Model-T Ford for consolidated deliveries, servicing Seattle department stores and other local businesses.

UPS’s “common carrier” service started in Los Angeles in 1922, adopting the uncommon practice of paying daily visits to customers to collect packages, and offering many other convenient delivery and payment services that we take for granted today. By 1930, they expanded their consolidated delivery services to the East Coast. But due to Interstate Commerce Commission (ICC) regulations, they couldn’t offer common carrier services in all locations, as they bumped up against state and interstate rules. They expanded to cities like Chicago in the 1950s, where they could legally operate, and then waged legal battles to operate elsewhere.

FedEx wants to fly

FedEx also hit regulatory walls (and lobbied government) after starting their air cargo express delivery business in 1973. UPS had been shipping packages on passenger planes, but FedEx wanted to use its own dedicated aircraft. They were restricted by size until air cargo deregulation in 1977, which gave them the legal ability to fly larger planes.

Deregulation changed everything

UPS and FedEx’s deregulation battles were just part of the movement to cut back government restrictions in transportation. Throughout the 1970s and 1980s, Congress passed multiple acts, deregulating not just air cargo, but trucking, surface freight forwarding and railroads. This helped current transportation companies to grow, allowed new companies to enter the market, let them choose routes, and offer more affordable shipping.

The rise of technology

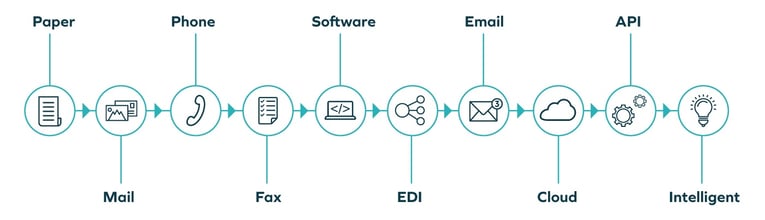

At the same time, technology was taking off. Before the computer’s mass market availability, logistics and transportation were tracked and arranged on paper and sent by snail mail, and later via phone. Of course, the fax machine, when not exhibiting a busy signal or jammed paper warning, let companies share schedules, estimates, contracts, billing and other business needs. The idea of sending data through a phone line to be spit out on actual paper in another location was revolutionary at the time, saving days of back and forth mailing.

Computers and spreadsheets ruled

Then came the computer age. Tracking moved to spreadsheets or on premise computer programs called Transportation Management Systems.

The next game changing innovation lead shippers to the internet and email. Companies ditched the paper shuffling in lieu of more instant communication and data transfer. Transportation management systems (TMS) rose in prominence as a great opportunity for efficiency and cost savings. These programs started simple, but as users became more dependent on their computers, their functionality grew, module by module.

TMS laggards still haven’t phased out, but the next generation of TMS started moving shipping communications to the cloud, where many (but not all) live today. On premise software is still the standard at most companies, but many legacy TMS makers now also offer cloud options.

Transportation Management Systems

Today’s companies are different. They are examining their internal systems and workflows from the ground up and looking for TMS solutions that don’t just give them a competitive edge, but also integrate with the rest of their internal software systems, provide real-time data exchange, and dynamically adjust to market fluctuations, always pointing the shipper to the lowest true shipping cost.

Legacy Transportation Management Systems

Companies are probably most familiar with legacy TMS solutions. Legacy TMS software is represented by:

- Modularized features. There are frequently different workflows for different shipment types and many of the modules don’t work well together. Instead of flowing into other enterprise systems, where a user can access the software with no barriers, the user has to log in and out of the TMS system and the enterprise system. A legacy TMS module is clunky and time consuming, disrupting the workflow.

- Treats every mode as a standalone. Different shipment types shouldn’t require a different booking process, but they do in legacy systems. Switching between shipment types and modes in the software system is not user-friendly.

- Manual to operate. A TMS system should be more advanced than a giant Excel spreadsheet, pulling in complete data from the enterprise system so fulfillment can be automated.

- Limited data. If you can’t get an accurate shipping costs when choosing options in the TMS, what’s the point of using it? Legacy TMS systems that use limited data provide limited help, and waste company resources.

- Labor intensive. With a legacy system, the shipment processing is labor intensive. It doesn’t have to be that way, if your TMS is properly integrated with the enterprise and warehouse management system.

- Usually only for large companies. Small companies can benefit from plug-in or cloud-based TMS software that is also affordable. Traditional TMS software is expensive and built for very large companies.

- Long implementation times. Legacy and on-premise transportation management systems are complex and difficult to setup and configure. Typical implementation times for these systems can be 9-12 months or longer.

- No checks and balances. The notion of “garbage in – garbage out” is an apt one for legacy TMS systems. Sending incomplete or bad data to a shipping company will still result in a price quote, it will just be wrong.

- Delayed data. Today’s technology supports real-time data transfers. Legacy TMS solutions do not.

Modern Transportation Management Systems

We started ShipHawk to alleviate costly TMS limitations, starting with shipping cost. Our first goal was to help shippers accurately predict the cost of shipping an order before it was bought, paid for, shipped and delivered. We wanted to reduce or eliminate costly rebills and margin erosion due to improperly calculated shipping prices.

And no matter how much functionality we added, we wanted the system to be accessible to shippers of all sizes, not just the Fortune 500. We recognized that to compete in today’s marketplace, small and medium sized shippers need world class tools capable of driving competitive efficiencies.

Make sure the system is a benefit to everyone

In today’s marketplace, shipping touches almost every department. Our next goal was to make sure the system was capable of meeting every department’s needs. Modern organizations are more complex than ever before and access to accurate logistics data is imperative to their success.

- Marketing - Which prospects are being marketed to? What is the cost to distribute products? How does that cost impact customer acquisition costs and order margins? Which customers offer the best margin opportunities?

- IT - How much bandwidth is taken up adding and maintaining logistics integrations and in house systems? ShipHawk maintains all carrier integrations and provides seamless updates to the cloud.

- Finance - No more waiting for logistics data. See data up front. Access to policy controls without going to the IT team.

- eCommerce - We live in a world of multiple distribution points and omnichannel fulfillment. These complex distribution processes require robust customer communication tools so customers are always in the know and shipping is fast, accurate, and inexpensive.

- Operations - Process orders faster and at a lower cost. Reduce errors and damage. Have immediate access to data and reporting for other departments.

- Customer success - Make customers happier. Reduce call volumes for order updates and shipping problems.

- Executive - Sell more. Convert more. Improve margins. Grow the business. Make more money.

10 Requirements to Meet Our Goals

We set a high bar and we knew that we needed some cutting edge software to make a real impact. We boiled the work down to these 10 initial requirements:

1. Build the best shipping cost optimizer- Account for both hard shipping costs and soft shipping costs

- Work with all modes and all carrier types

- Leverage data to find lower shipping costs

3. Allow shippers to make data-driven decisions

- Reporting

- Data and analytics

- Tools to make changes without needing development work

- Don’t make shippers wait for the IT backlog to clear in order to add carriers, adjust subsidies or shipping rules.

- Allow all departments access to make the changes at any time

- Better optimize each order

- Provide benchmark data

- Provide alternatives for service issues

- Multi-carrier rating (simply better results that are less expensive)

- Account for more than just weights and dims

- Packing optimization

- Pack items in boxes, boxes in pallets, and pallets on trucks - all without requiring hardware

- Offer various levels of workflow automation from manual to fully auto

- Reduce labor and fulfillment costs

- Customer interface

- Drop ship functionality

- Carrier and 3PL portal

- Track and trace

- Buyer notifications and communication

- TMS 2.0

The result has fueled great growth (ShipHawk ranked #12 on the 2017 Inc 500 and #1 in the Transportation and Logistics category) and is changing the way companies ship. By building software to address the requirements referenced above, ShipHawk is now reducing companies’ hard shipping costs by up to 20% and reducing their soft shipping costs by up to 50%.

We define Transportation Management System 2.0 as one that is automated and data-driven. This approach allows businesses to automate best practices, examine the data, refine the system, and repeat.

ShipHawk is now reducing companies’ hard shipping costs by up to 20% and reducing their soft shipping costs by up to 50%.

Conclusion

ShipHawk offers many more bells and whistles than those named in this article, but we thought it was important to share our journey so you can understand the “Why” behind the work we do.

Reach out to us if you’d like to see the impact ShipHawk technology can have on your business.